GlobalFoundries Dresden

Predictive Maintenance for the Production of Semiconductors

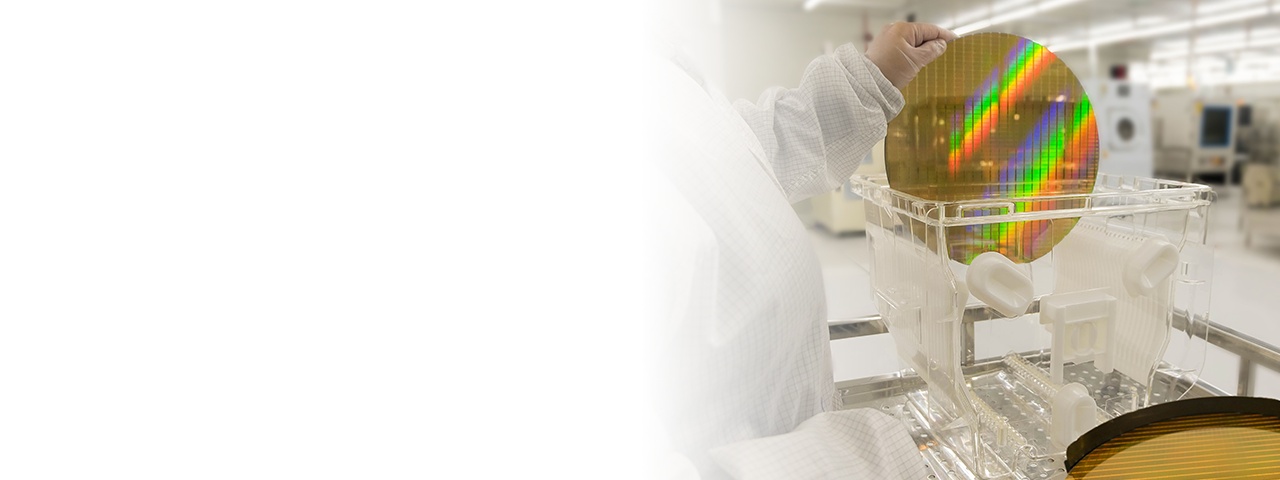

GlobalFoundries is a U.S. semiconductor manufacturer with more than 16,000 employees worldwide. The company produces microchips on behalf of more than 250 customers in the automotive and manufacturing industries, computers, mobile communications and consumer electronics, among others. Therefore GlobalFoundries operates production sites in Dresden, the USA and Singapore. The Dresden plant is considered the largest and most modern semiconductor plant in Europe. The microchips are manufactured in clean rooms in more than 1,000 process steps. Both the equipment and each of the individual production stages are strictly monitored to prevent failures or quality fluctuations in production. The control valves for ultrapure water, an important supply medium in semiconductor production, pose a particular challenge. Defects in these valves were previously unpredictable and could potentially lead to disruptions. To continuously monitor the ultra-pure water valves at GlobalFoundries, T-Systems MMS developed an IoT solution based on its Cloud Shopfloor Intelligence platform in collaboration with the Smart Systems Hub and other partners.

Customer Benefits

Ensure higher reliability of production equipment

Digitized monitoring saves on personnel and time

Permanent condition monitoring and data-supported, demand-oriented maintenance

Reference Overview

Task

The previous monitoring of production-critical ultra-pure water valves by employees on site is to be replaced by sensor technology. Defects are to be detected at an early stage or in advance and further insights gained.

Solution

Special acoustic sensors process the acoustic data within an edge computing hardware with machine learning algorithms and transmit them to the "Cloud Shopfloor Intelligence" platform for display on various dashboards.

Result

Thanks to the scalable edge computing and cloud solution, the data obtained from the highly complex processes is evaluated and processed in such a way that the status of the valves can be retrieved at any time. Beginning defects can be detected at an early stage.

About GlobalFoundries Management Services LLC & Co. KG

The semiconductor manufacturer GLOBALFOUNDRIES employs more than 16,000 people worldwide. More than 3,000 technicians, engineers and specialists from all over the world work at the company campus in Dresden. GLOBALFOUNDRIES has helped to establish the Free State of Saxony as a leading micro- and nanoelectronics center in Europe and has significantly advanced the development of new IoT and connectivity system solutions with the Smart Systems Hub.