Fabmatics

Analytics Platform for Optimal Robot Performance

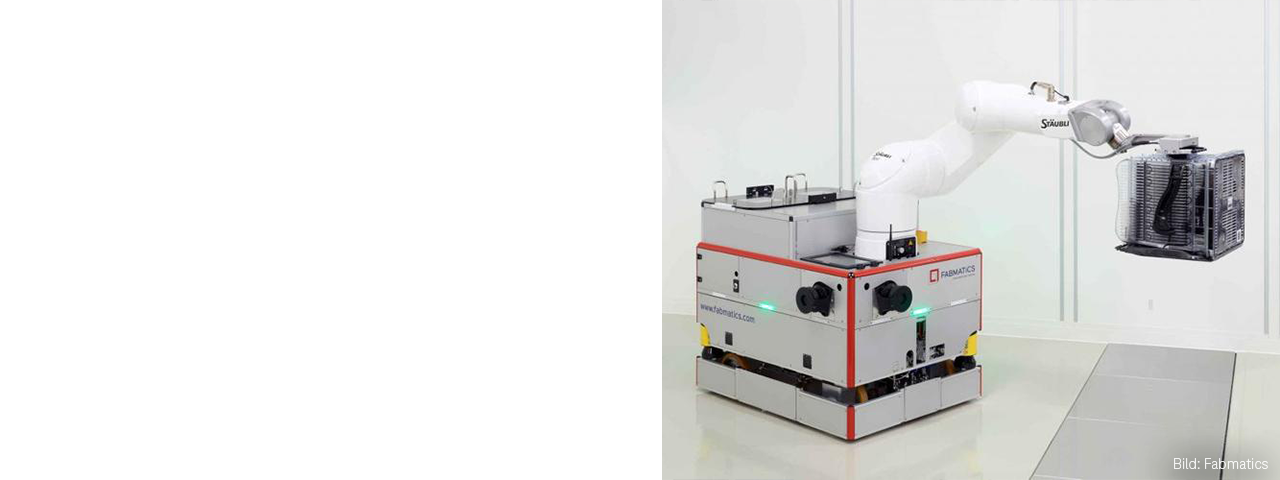

Due to the global chip shortage, it is essential to use the existing production capacities in an optimal way for maximum output. Automation specialist Fabmatics, headquartered in Dresden, Germany, supplies semiconductor manufacturers worldwide with handling robots. These autonomous robotic systems transport the wafers, which are later used to manufacture chips, to the individual stations in the clean room. In order to further optimize these highly complex logistics processes, Fabmatics would like to offer its customers digital services for process monitoring in the future. In a joint project, Fabmatics, T-Systems MMS, the Smart Systems Hub and Wandelbots developed the prototype for a cloud-based data management platform.

Customer Benefit

Prospective expansion of the Fabmatic portfolio to include new digital services

Offer technology and analysis service from a single source

Conclusions for the optimization and further development of the transport robots

Reference Summary

Task

Develop approaches for new digital customer service based on existing data.

Solution

First prototype of a cloud-based data management platform.

Result

Transparency of all condition data, blueprint for further product development.

About Fabmatics

Fabmatics GmbH, headquartered in Dresden, has been implementing customer-specific automation projects in the semiconductor industry for over 30 years, as well as for companies in the electronics, medical technology, pharmaceutical and photovoltaics sectors. The product range includes hardware and software for the automation of handling, transport and storage processes as well as solutions for product identification and localization - all under the special conditions of the cleanroom. Around 250 people work for customers in the high-tech industry at the sites in Dresden and the USA.